Double Molds Fast Cooling Popsicle Maker Machine Sorbet LJB160-2-1600W-220V

You are here:

- Home

- Refrigeration equipment

- Popsicle Maker Machine

- Double Molds Fast Cooling Popsicle Maker Machine Sorbet LJB160-2-1600W-220V

- Power: 1600W

- Raw Materials: Fruit/Yogurt/Drinks/Ice Cream

- Key Selling Points: Variety of Popsicle Shapes

- Warranty: Rationale Accessories

- Capacity: Two Molds

- Ice Making Method: Compressor Refrigeration

- Applicable Places: Ice Shop/Hotpot Shop/Catering

- Shell Material: Stainless Steel Color

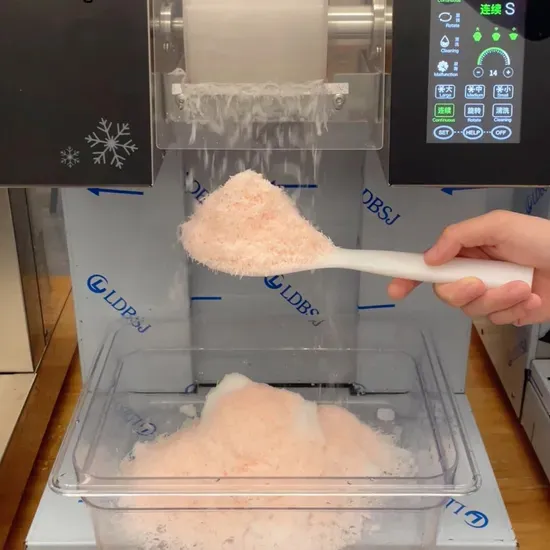

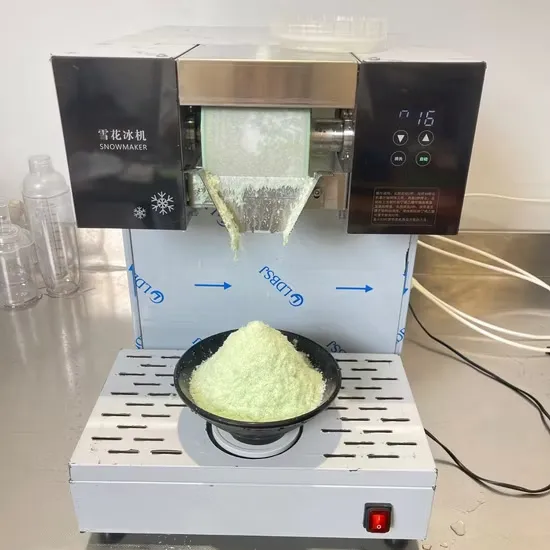

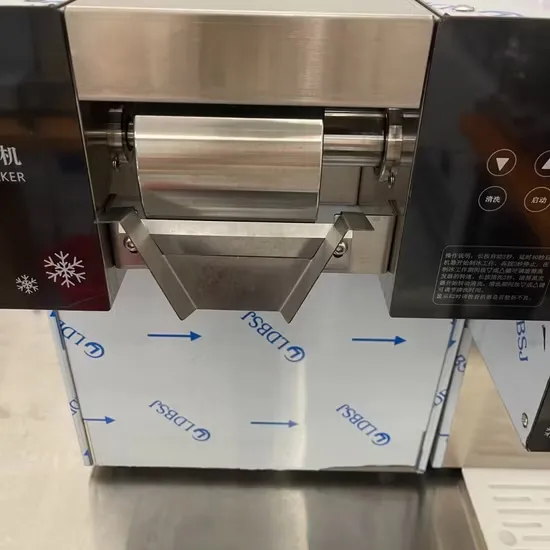

Our popsicle maker is a device used to make popsicles or ice lollies. It quickly freezes a liquid mixture (such as juice, milk, syrup, etc.) into popsicles through a built-in freezing system. Popsicle makers are usually equipped with multiple molds to make multiple popsicles at the same time. The design of the equipment includes a liquid injection tank, a freezing chamber, and a popsicle removal mechanism to ensure that the process is efficient and easy. Operation is usually as simple as pouring in the liquid, setting the freezing time, and waiting for the freezing to complete. The popsicle maker is suitable for use in places such as homes, restaurants and food processing plants, helping to quickly create a diverse range of popsicles.

1.Rapid Freezing:Built-in freezing system can quickly freeze the liquid mixture into popsicles, shortening the production time.

2.Multi-mold Design: Equipped with multiple molds, it can make multiple popsicles at the same time, increasing productivity.

3.Simple Operation: Intuitive control panel and operation flow make the production process simple and easy.

4.Easy to Clean: Removable molds and cleaning design make it easy for daily cleaning and maintenance.

5.Durable Material: made of durable material to ensure long term use and wear resistance.

1.Family Kitchen:

Purpose: Make homemade popsicles or ice lollies to provide healthy and tasty frozen desserts for family members.

Example: Use the popsicle machine to make various flavors of popsicles to satisfy different tastes at family gatherings or children’s birthday parties.

2.Restaurants and coffee shops:

Purpose: Make specialty popsicles as dessert or drink toppings to enhance menu variety.

Example: Restaurants use popsicle machines to make creative popsicles, such as fruit-mixed popsicles or cream popsicles, which are served to customers as desserts after meals.

3.Food Processing Plant

Purpose: Mass production of popsicles for retail or distribution to meet market demand.

Example: Food processing plants use popsicle machines to produce various flavors of popsicles, package and distribute them to supermarkets and convenience stores.

4.School and Community Events:

Purpose: Popsicles are produced for student or community events as a cool reward or event snack.

Example: Schools use popsicle machines to make healthy fruit popsicles for students as part of summer activities.

| Model | Capacity | Voltage(customizable) | Power | Cooling | user interface | Size (L*W*H) | Refrigerant | ||||||||

| LJB160-2 | Dual Mold | 220V/50Hz | 1600W | Air | microcomputer control | 78*54*97.5CM | R22 |